Our Expert Services in Welding Engineering, Metal Fabrication and 3D Technologies.

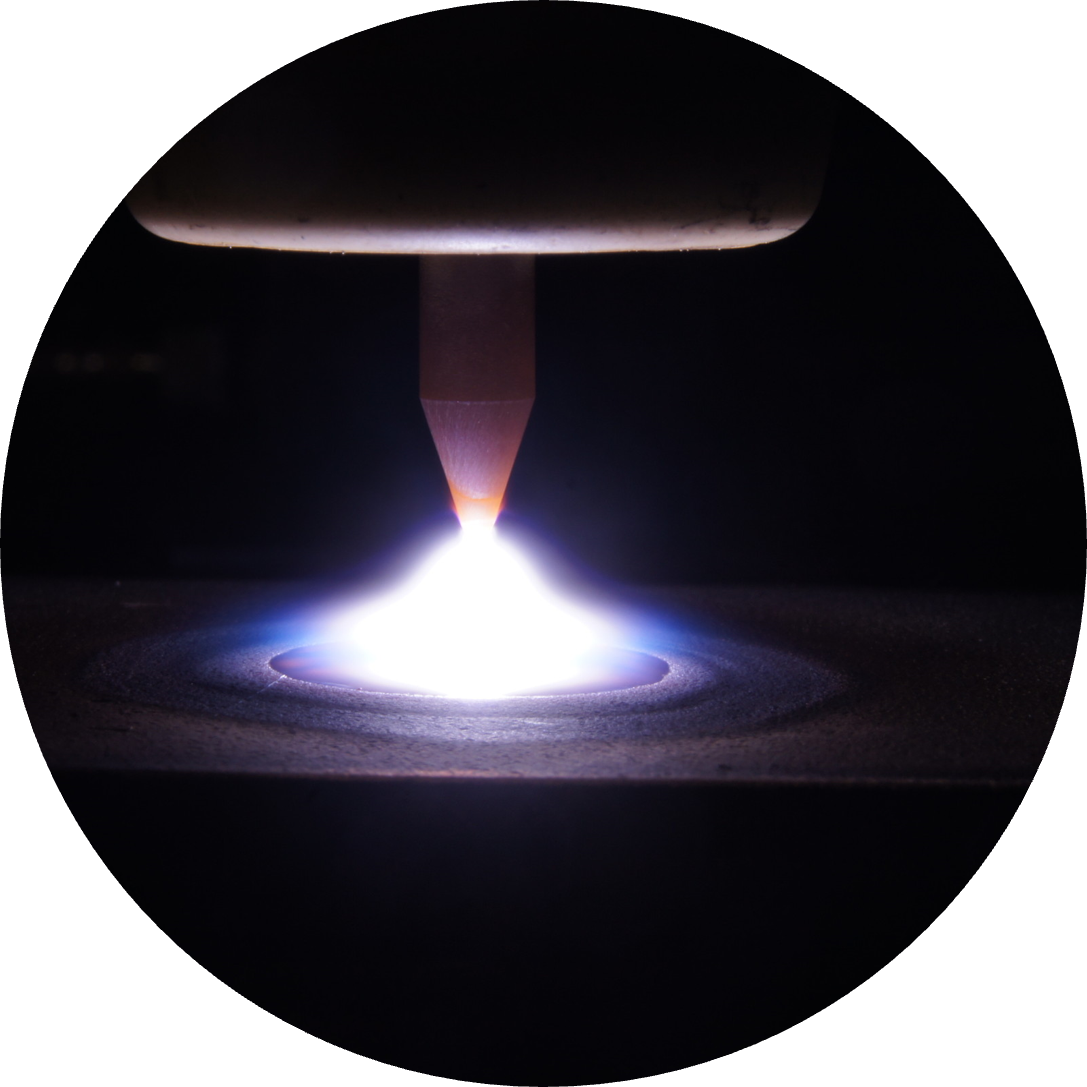

Every successful project starts with a robust foundation. Whether you aspire to innovate with your own business or enhance existing processes, our expertise in welding engineering can elevate your vision. We specialize in turning your concepts into reality with precision and professionalism.

Our dedicated team is committed to helping you navigate the complexities of welding code compliance and inspection. Your narrative deserves to stand out in a crowded digital environment, and we ensure that your unique capabilities differentiate you in the marketplace.

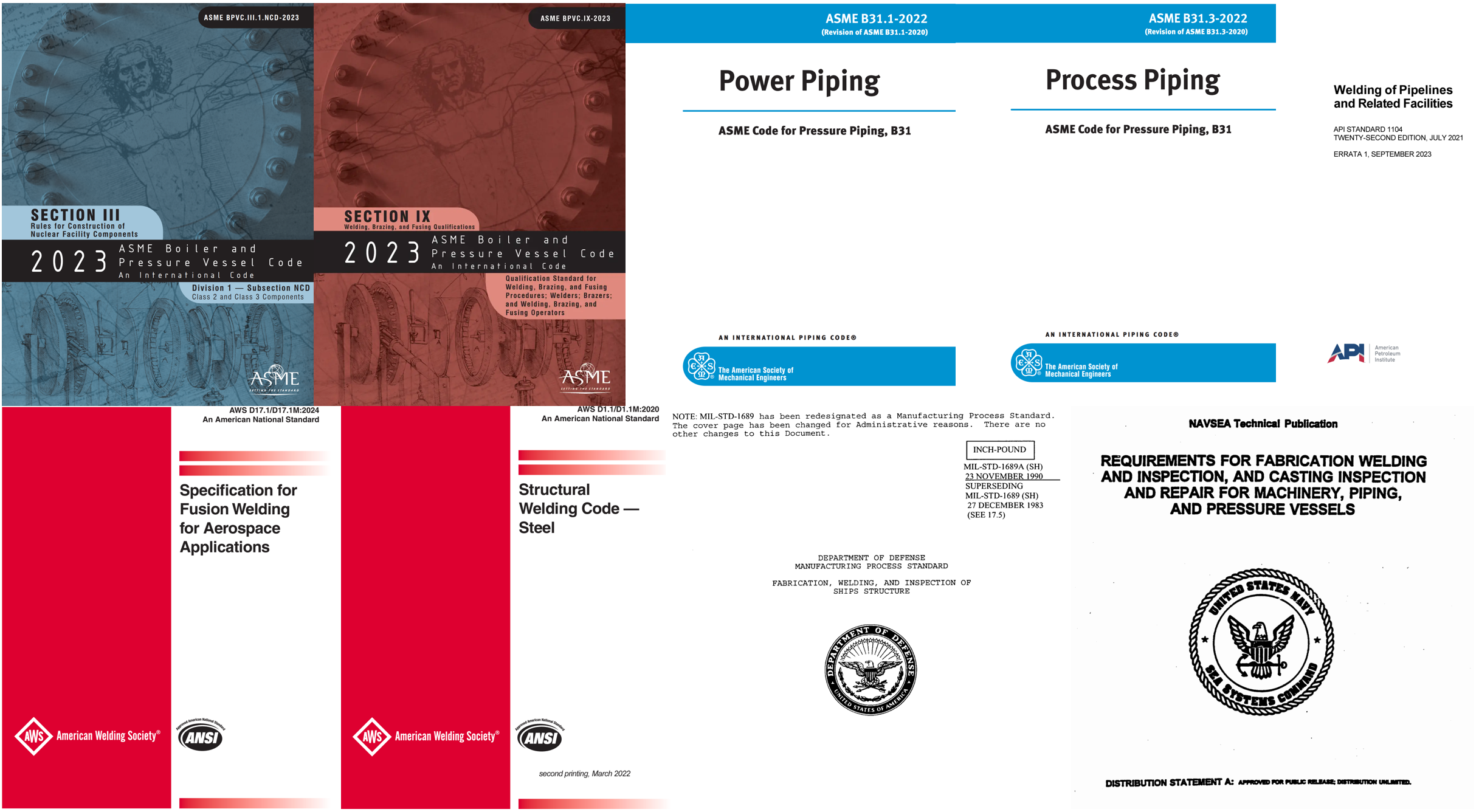

Welding Code Compliance

Fusioneering's Welding Code Compliance service guarantees that every single aspect of your welding operations consistently aligns with the highest industrial code standards, thereby ensuring both structural integrity and operational safety across all projects. Our highly experienced expert team specializes in skillfully navigating a diverse range of codes, such as the American Welding Society (AWS) D1.1 for steel structures, the ASME Boiler and Pressure Vessel Code, and the various API standards that are relevant to pipeline welding. We perform thorough and comprehensive reviews and evaluations to meticulously verify strict adherence to these important specifications, granting our clients invaluable peace of mind that their welding processes are fully compliant with all necessary regulatory requirements. By remaining thoroughly updated on revisions to these industry standards, we empower clients to not only maintain continuous compliance but also to significantly improve overall project quality and enhance operational performance.

Welding Inspection

Fusioneering's Welding Inspection services not only meet but exceed industry standards, encompassing a wide array of renowned guidelines including ASME, AWS, API, NAVSEA, and MIL-STD. This commitment ensures rigorous compliance while delivering high-quality results that our clients can trust. Our team of AWS QC-1 certified inspectors excels in conducting both in-person and remote inspections, allowing for comprehensive assessments of weld quality and the identification of potential issues early in the fabrication process. We prioritize strict adherence to project timelines and budgets, providing proactive solutions that effectively keep projects on track, regardless of their complexity. Our unwavering commitment to excellence guarantees compliance with all necessary safety standards, instilling confidence in our clients across diverse commercial, governmental, and military projects. At Fusioneering, we not only foster reliability but also peace of mind, ensuring that every weld remains in line with stringent standards for successful execution and operational integrity. Additionally, our remote visual inspections are conducted on a global scale, accommodating all applicable codes to fully support the diverse needs of international project requirements.

Welding Procedure Qualification

Our Welding Procedure Qualification service meticulously ensures that your welding processes not only meet but also exceed industry standards and specific project requirements. By systematically evaluating and rigorously testing welding procedures, we verify their effectiveness and compliance with essential codes such as AWS, ASME, and API. Our highly skilled team conducts thorough assessments, including comprehensive mechanical testing and advanced non-destructive evaluations, to validate the reliability and quality of the welds involved. This invaluable service not only significantly enhances the safety and integrity of your projects but also provides you with peace of mind through documented evidence of compliance and performance, all tailored to meet your unique operational needs effectively.

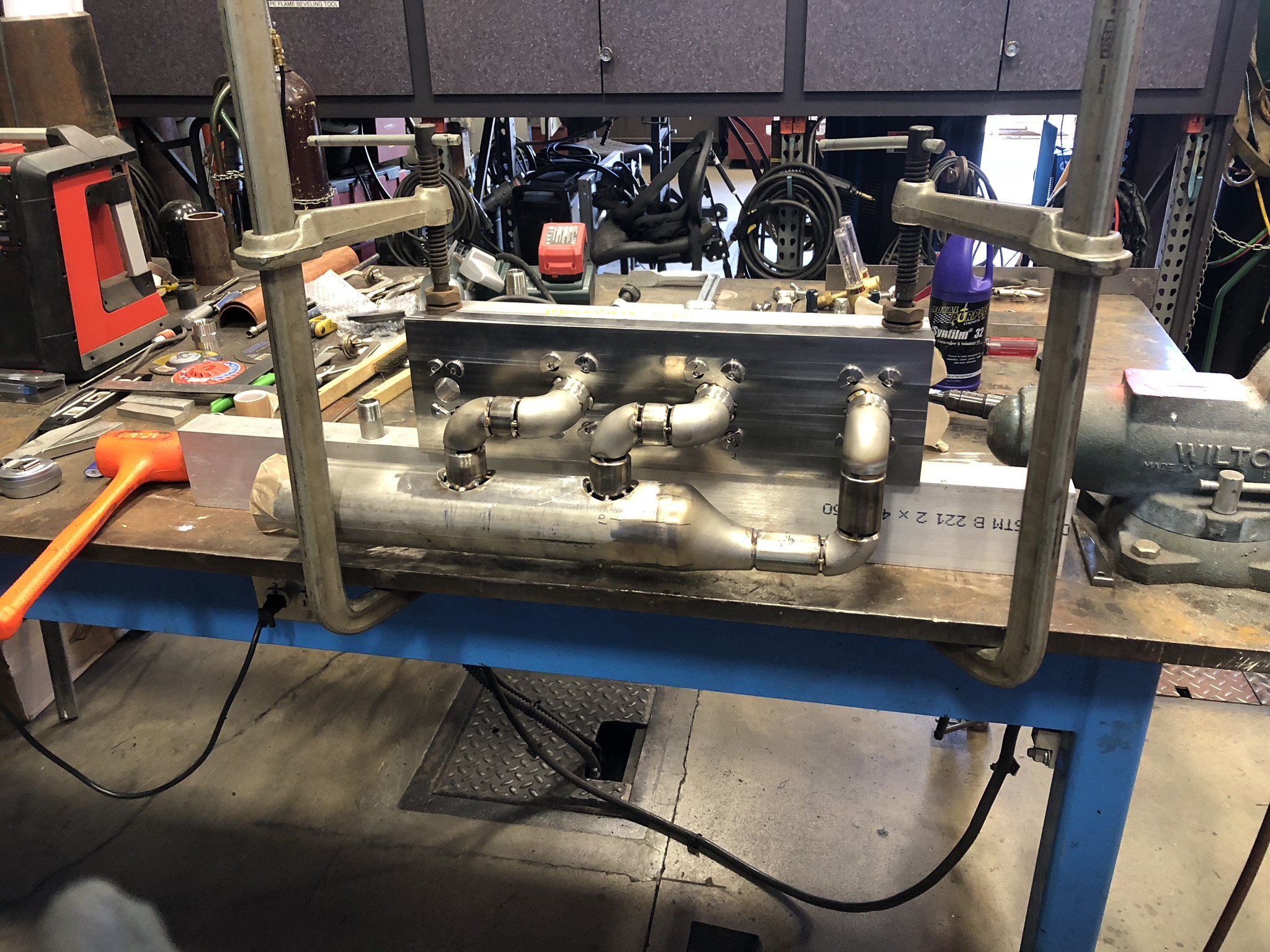

Piping and Pressure Vessel Fabrication

At Fusioneering, we recognize that the integrity of piping and pressure vessel systems is critical to safety and functionality. Our comprehensive fabrication services are meticulously designed to comply with industry-leading standards, including ASME codes, to ensure each project meets stringent safety and quality benchmarks.

Our experienced engineers and technicians are adept at navigating the complexities of ASME B31.1 for power piping and ASME B31.3 for process piping, tailoring our approach to align with client specifications while satisfying regulatory obligations. This rigorous adherence to code compliance guarantees that our fabricated systems not only perform optimally but are also resilient under challenging conditions.

By emphasizing quality in every aspect of our fabrication process, we support our clients in achieving operational reliability and compliance, ultimately contributing to the success of their projects.

Rapid Prototyping

Fusioneering's Rapid Prototyping Service accelerates product development by quickly transforming concepts into precise physical prototypes. Utilizing advanced 3D CAD technology, we enable thorough testing before production, shortening development timelines and enhancing design accuracy. Our integration of welding expertise and failure analysis ensures products exceed industry quality standards. Our experienced team provides oversight and collaborates with clients to meet unique requirements, fostering innovation and addressing challenges. In a competitive landscape, our service offers a strategic advantage, empowering clients to minimize risks and maintain their edge. We focus on delivering exceptional results that align with clients' visions for the future.

Fabrication Packages

Our fabrication packages are meticulously crafted to ensure a seamless transition from design to production. Each package includes comprehensive design drawing data, which outlines the specifications and parameters for the project. Additionally, we provide a detailed bill of materials that lists all components required for fabrication, ensuring clarity and efficiency. Cut lengths are precisely calculated and documented, which facilitates accurate material processing and reduces waste. Moreover, our packages encompass all standard elements found in fabrication drawings, such as assembly instructions and tolerances, to ensure compliance with industry standards and specifications. This holistic approach guarantees that each project is executed with precision and professionalism, delivering high-quality results that meet our clients' expectations.

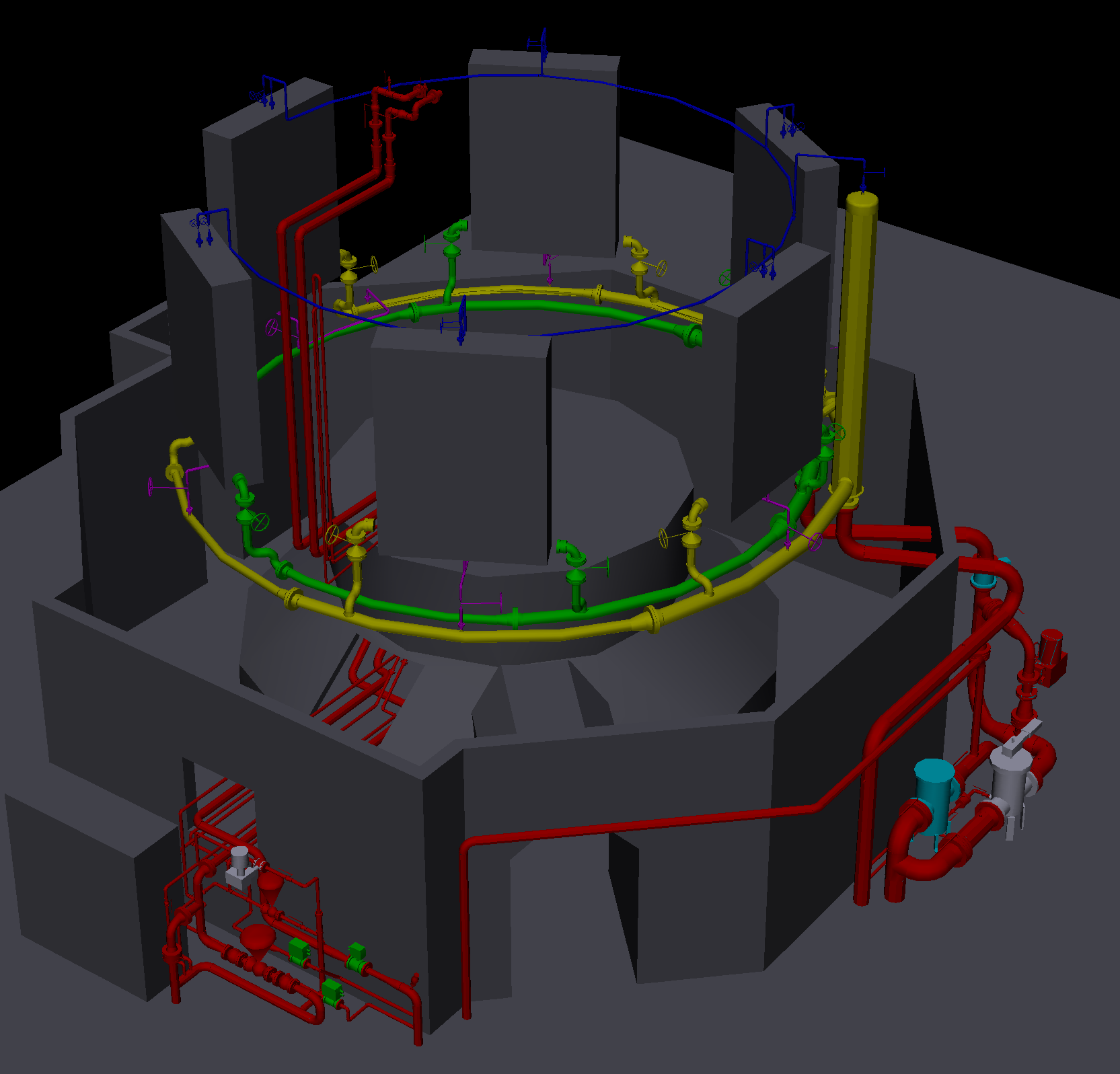

3D CAD

Our 3D CAD services at Fusioneering provide precise and highly efficient design solutions that are meticulously tailored to meet the complex and evolving demands of welding engineering and related fields. Utilizing state-of-the-art advanced software, we create intricate and detailed three-dimensional models that significantly enhance visualization and facilitate seamless integration into existing systems and processes. Our extensive expertise allows us to optimize designs not only for manufacturability but also for functionality, thereby aiding in the significant reduction of both production costs and time. By leveraging our sophisticated 3D CAD capabilities, clients can expect not only improved project outcomes and enhanced collaboration among stakeholders, but also comprehensive and thorough documentation that ensures complete compliance with the highest industry standards.

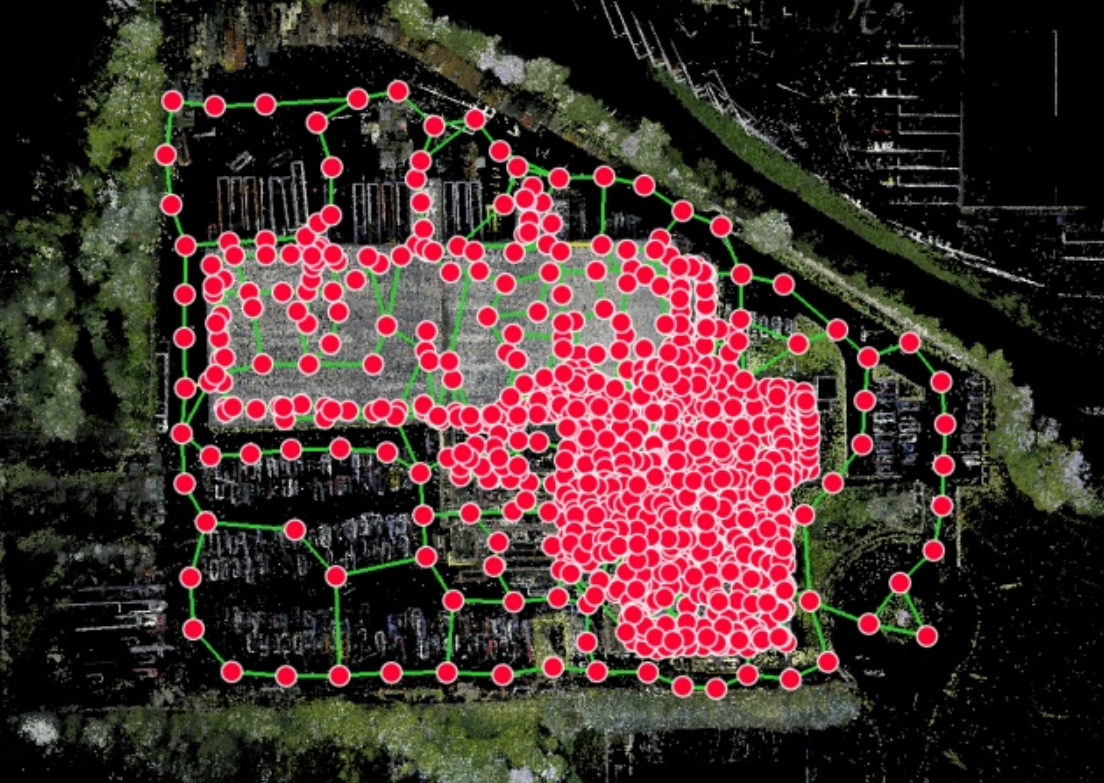

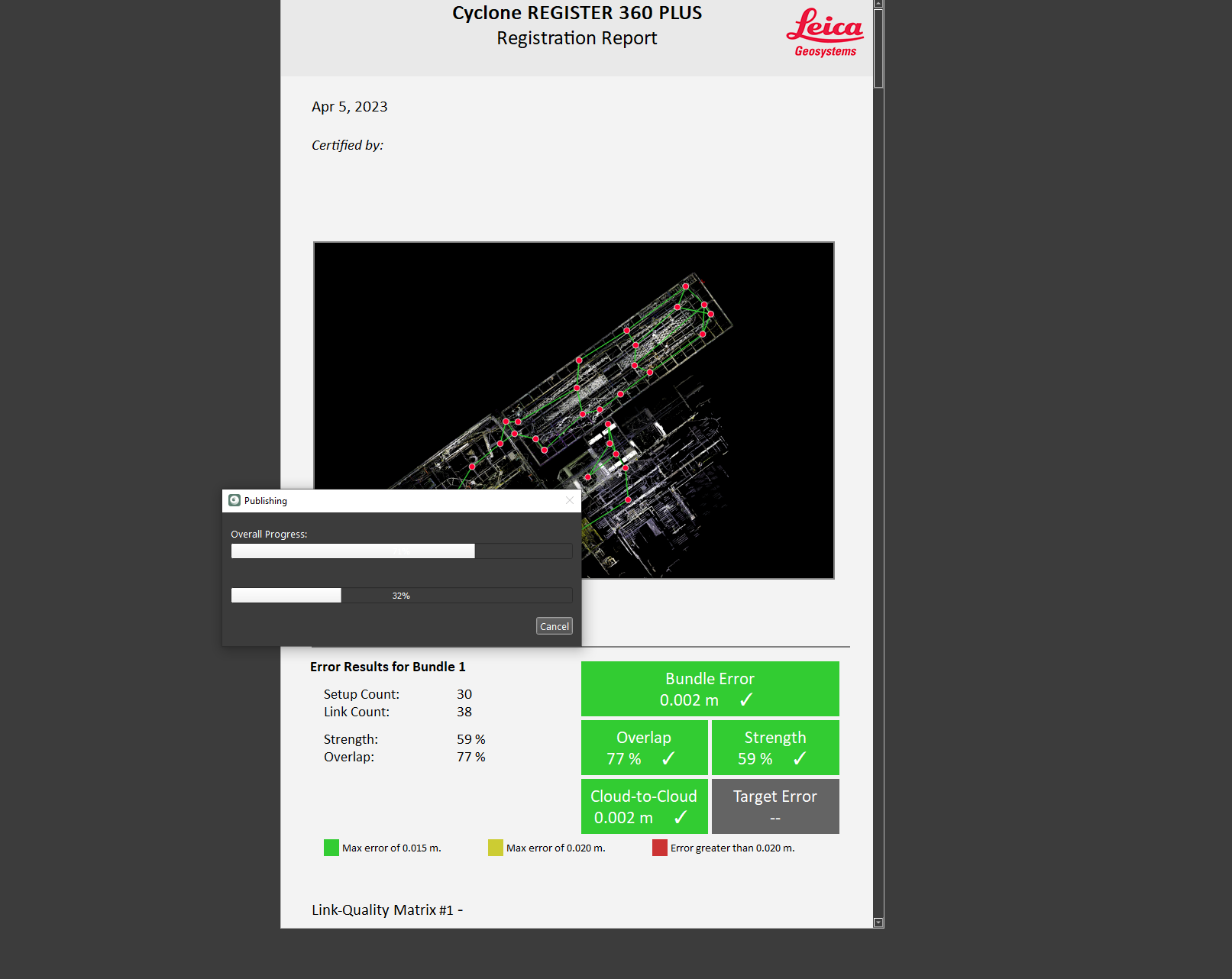

3D Terrestial Laser Scanning

Our 3D Terrestrial Laser Scanning Services provide precise and efficient solutions for capturing complex spatial data in various environments, including urban landscapes and intricate industrial sites. Using advanced laser scanning technology, we are able to create highly accurate and detailed 3D models of various structures, terrains, and industrial facilities. This non-invasive method significantly enhances project planning while simultaneously reducing overall costs and minimizing disruptions during the data collection phase. The meticulously detailed point cloud data generated facilitates comprehensive analyses, aiding in crucial decision-making processes, design improvements, and effective project management. By leveraging our extensive expertise in terrestrial laser scanning, clients can fully benefit from improved accuracy and enhanced visualization capabilities for their diverse projects.

Laser Scanning Post Processing

Our Laser Scanning Post Processing service is specifically designed to effectively transform raw point cloud data into actionable insights that are invaluable for various projects, thereby facilitating precise modeling and detailed analysis for a wide variety of applications across numerous industries. Utilizing advanced software tools and methodologies, we meticulously process and refine the data collected from our terrestrial laser scans, ensuring exceptionally high levels of accuracy and intricate detail that our clients can rely on. This comprehensive service encompasses essential processes such as data registration, noise reduction, and the creation of sophisticated 3D models that not only meet specific project requirements but also adhere to industry standards. Whether for large-scale construction, intricate engineering projects, or historical preservation efforts, our expert post-processing solutions significantly enhance project efficiency and mitigate potential risks, ultimately leading to informed decision-making and improved outcomes for all involved stakeholders, thus elevating the overall quality of the work delivered.

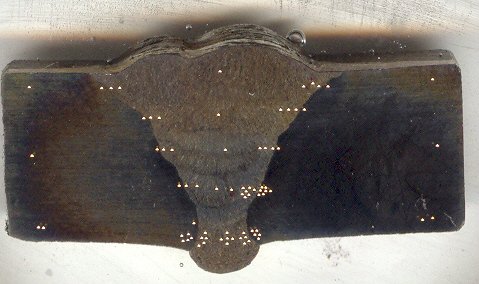

Industrial Art

Fusioneering offers specialized industrial art services that blend engineering expertise with creative design to transform functional structures into captivating works of art. Our team utilizes advanced welding techniques and innovative materials to create custom pieces that not only meet stringent compliance standards but also enhance the aesthetic value of industrial environments. By integrating artistry and engineering, we provide unique solutions that elevate the visual impact of industrial spaces while maintaining structural integrity and performance. Whether it's for public installations, corporate headquarters, or unique architectural elements, our industrial art services are tailored to meet the specific needs and vision of each client.

Custom Welding and Architectural Metal Fabrication

At Fusioneering, we specialize in custom welding and architectural metal fabrication services tailored to meet the unique needs of our clients. Our skilled team employs advanced techniques and state-of-the-art equipment to create durable, high-quality metal structures that seamlessly blend functionality with aesthetic appeal. Whether it’s intricate design elements for commercial projects or robust industrial components, we ensure strict adherence to industry standards and code compliance. Our commitment to precision and craftsmanship not only enhances the structural integrity of our products but also elevates the overall visual impact of any architectural endeavor.

Reverse Engineering/Failure Analysis

At Fusioneering, we prioritize accuracy and reliability in engineering. Our failure analysis and reverse engineering services enhance manufacturing and product performance. Identifying failure root causes is crucial. Our skilled team employs advanced techniques to analyze issues and provide insights to prevent future problems, minimizing downtime and costs.

Our reverse engineering services extract valuable information from existing products. We utilize state-of-the-art scanning and modeling tools to create precise digital versions of physical components, facilitating easy integration into new projects or updates.

Fusioneering blends technical expertise with a commitment to quality, ensuring projects align with industry standards and boost your market reputation. Whether addressing current product challenges or pursuing innovative designs, our team is ready to support your objectives. Enhance your engineering capabilities with Fusioneering's services and turn challenges into growth opportunities.

Freeze Seals

Freeze seals are a specialized service offered by Fusioneering to effectively isolate sections of piping systems during crucial maintenance or extensive repair work, all without the need for a complete system shutdown. This innovative and cutting-edge method involves using liquid nitrogen to rapidly freeze the contents of the pipe, thereby creating a solid ice plug that effectively prevents fluid flow. By utilizing freeze seal technology, our experienced team ensures minimal disruption to ongoing operations and significantly reduces downtime for clients across various industries. This highly efficient approach not only enhances safety but also ensures compliance with rigorous industry standards, making it an essential and invaluable service for maintaining the integrity and functionality of complex piping systems.

Welder Certification

Fusioneering proudly offers comprehensive Welder Certification services that strictly adhere to a range of stringent industry standards, including ASME, API, MIL-STD, Navsea, and AWS. Our certification process is meticulously conducted by highly qualified and certified AWS QC-1 inspectors, ensuring that each welder's skills and competencies are rigorously assessed against the highest benchmarks of quality and safety. We fully recognize the critical importance of having qualified welders in preserving structural integrity and ensuring compliance, which is why we prioritize thorough evaluations and precise documentation in our certification process. Our unwavering dedication to excellence guarantees that your welding personnel are not only certified but also exceptionally well-equipped to meet and overcome the challenges presented by today's demanding industrial environments.

Welder Training

At Fusioneering, our Welder Training service is meticulously tailored to meet your company's specific needs and project requirements. We understand that every organization has its own unique challenges and objectives, which is why we offer highly customized training programs designed specifically to enhance the diverse skills of your workforce. Our experienced and knowledgeable instructors utilize industry-relevant methodologies, thoughtfully integrating practical hands-on exercises with comprehensive theoretical knowledge to ensure that welders are exceptionally well-equipped to meet stringent code compliance and quality standards. By strategically aligning our training initiatives with your operational goals, we empower your team to achieve a high level of excellence in their welding practices, ultimately contributing to the overall success of your projects and significantly enhancing overall productivity in the process.