From Alchemy to Arc: A History of Welding and the Qualities of a Professional

From Alchemy to Arc: A History of Welding and the Qualities of a Professional

Metals have captivated humanity since their discovery, transforming societies from the Stone Age to the Bronze and Iron Ages. The ability to manipulate and join these materials, initially a blend of artistry and science, has been fundamental to progress. This essay will trace the historical development of welding, from its rudimentary beginnings intertwined with alchemy to the sophisticated techniques employed today, and then detail the key attributes to look for in a professional welder.

The early history of welding is inextricably linked to metallurgy. Ancient civilizations discovered and utilized metals like gold, silver, copper, tin, lead, and iron, initially for decorative purposes and later for tools and weaponry. The understanding of alloying, exemplified by the creation of bronze (copper and tin), demonstrated an early grasp of manipulating metal properties. This period also saw the rise of alchemy, a practice that while considered pseudoscience today, fueled much experimentation and observation. Alchemists, often shrouded in mystery, sought the mythical philosopher's stone, believing they could transmute base metals into gold and unlock the secrets of the universe. As Scientific American notes, these "metal craftsmen" laid the groundwork for modern chemistry, developing crucial techniques and insights into metal behavior.

This all emphasizes that while alchemy might seem far removed from modern welding, it represents an important early chapter in our understanding of metal properties. Figures like Robert Boyle, considered the father of modern chemistry, were initially influenced by alchemical pursuits. Their eventual shortcomings underscore the importance of scientific understanding, particularly the atomic structure of elements, which was centuries away from being discovered. The article cleverly points out that transmutation is theoretically possible with modern technology like particle accelerators, albeit impractical, highlighting the vast leap in knowledge since the days of alchemy.

The Industrial Revolution marked a turning point in welding technology. The increasing demand for manufactured goods and the rapid development of infrastructure spurred the invention of new welding techniques and equipment. This evolution accelerated further during the World Wars, as the need for efficient and reliable joining methods became critical for military applications. Arc welding, resistance welding, and gas welding emerged, all building upon the fundamental principle of fusing materials together by applying heat and pressure.

Today, welding has become a highly specialized profession requiring extensive training and certification. Fusioneering is a company specializing in commercial construction, emphasizes the importance of employing skilled and certified welders. Their welders, for instance, hold ASME (American Society of Mechanical Engineers) certification, demonstrating their expertise in working with boilers and pressure vessels according to stringent industry standards.

So, what qualities should one look for when seeking a professional welder? The ASME certification, as mentioned by Fusioneering, is a crucial indicator of competence. This certification validates that the welder has undergone rigorous training and testing and possesses the necessary skills to perform welds that meet specific codes and standards. Beyond certification, experience is invaluable. An experienced welder has encountered a diverse range of welding challenges and developed the problem-solving skills to address them effectively.

Furthermore, a professional welder should possess:

Technical Proficiency: A deep understanding of various welding techniques (SMAW, GMAW, GTAW, etc.), metal properties, and weld symbols is essential.

Precision and Attention to Detail: Welding requires meticulous execution to ensure strong, reliable, and aesthetically pleasing joints.

Safety Consciousness: Welding involves inherent risks, including exposure to fumes, sparks, and electric shock. A professional welder prioritizes safety and adheres to all relevant safety protocols.

Problem-Solving Skills: Every welding project presents unique challenges. A skilled welder can analyze the situation, identify potential problems, and implement effective solutions.

Communication Skills: Effective communication with clients, engineers, and other team members is crucial for ensuring that the welding project meets all requirements.

Adaptability: The ability to adapt to different work environments, materials, and welding techniques is essential in a dynamic field.

In conclusion, the history of welding is a testament to human ingenuity and the enduring pursuit of manipulating metals to build and create. From the mystical practices of alchemy to the sophisticated techniques of modern welding, the journey has been one of continuous learning and innovation. When seeking welding services, prioritizing professionals with the right certifications, experience, and a commitment to skill, safety, and communication is paramount to ensuring the successful execution of any project. The modern metal artist, as Fusioneering aptly describes them, plays a critical role in constructing the world around us, carrying on a tradition that spans millennia.

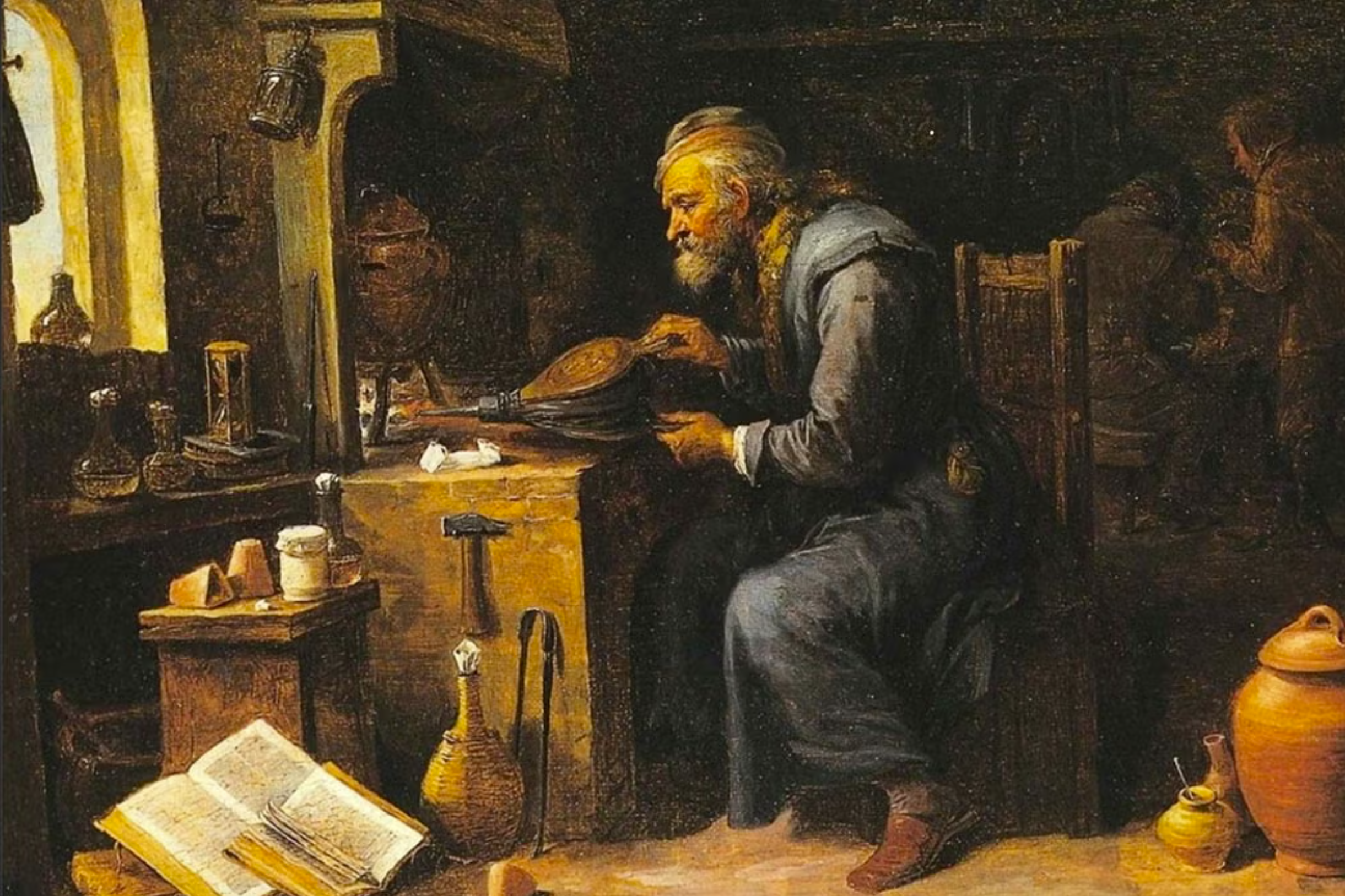

Scene in a Alchemists’ Laboratory.

By: Ryan Dean

Metals have captivated humanity since their discovery, transforming societies from the Stone Age to the Bronze and Iron Ages. The ability to manipulate and join these materials, initially a blend of artistry and science, has been fundamental to progress. This essay will trace the historical development of welding, from its rudimentary beginnings intertwined with alchemy to the sophisticated techniques employed today, and then detail the key attributes to look for in a professional welder.

The early history of welding is inextricably linked to metallurgy. Ancient civilizations discovered and utilized metals like gold, silver, copper, tin, lead, and iron, initially for decorative purposes and later for tools and weaponry. The understanding of alloying, exemplified by the creation of bronze (copper and tin), demonstrated an early grasp of manipulating metal properties. This period also saw the rise of alchemy, a practice that while considered pseudoscience today, fueled much experimentation and observation. Alchemists, often shrouded in mystery, sought the mythical philosopher's stone, believing they could transmute base metals into gold and unlock the secrets of the universe. As Scientific American notes, these "metal craftsmen" laid the groundwork for modern chemistry, developing crucial techniques and insights into metal behavior.

This all emphasizes that while alchemy might seem far removed from modern welding, it represents an important early chapter in our understanding of metal properties. Figures like Robert Boyle, considered the father of modern chemistry, were initially influenced by alchemical pursuits. Their eventual shortcomings underscore the importance of scientific understanding, particularly the atomic structure of elements, which was centuries away from being discovered. The article cleverly points out that transmutation is theoretically possible with modern technology like particle accelerators, albeit impractical, highlighting the vast leap in knowledge since the days of alchemy.

The Industrial Revolution marked a turning point in welding technology. The increasing demand for manufactured goods and the rapid development of infrastructure spurred the invention of new welding techniques and equipment. This evolution accelerated further during the World Wars, as the need for efficient and reliable joining methods became critical for military applications. Arc welding, resistance welding, and gas welding emerged, all building upon the fundamental principle of fusing materials together by applying heat and pressure.

Today, welding has become a highly specialized profession requiring extensive training and certification. Fusioneering is a company specializing in commercial construction, emphasizes the importance of employing skilled and certified welders. Our welders, for instance, hold ASME (American Society of Mechanical Engineers) certification, demonstrating their expertise in working with boilers and pressure vessels according to stringent industry standards.

So, what qualities should one look for when seeking a professional welder? The ASME certification, as mentioned previously, is a crucial indicator of competence. This certification validates that the welder has undergone rigorous training and testing and possesses the necessary skills to perform welds that meet specific codes and standards. Beyond certification, experience is invaluable. An experienced welder has encountered a diverse range of welding challenges and developed the problem-solving skills to address them effectively.

Furthermore, a professional welder should possess:

Technical Proficiency: A deep understanding of various welding techniques (SMAW, GMAW, GTAW, etc.), metal properties, and weld symbols is essential.

Precision and Attention to Detail: Welding requires meticulous execution to ensure strong, reliable, and aesthetically pleasing joints.

Safety Consciousness: Welding involves inherent risks, including exposure to fumes, sparks, and electric shock. A professional welder prioritizes safety and adheres to all relevant safety protocols. A competent professional welder understands the risks involved before stepping into any project. They need to have a strong Situational Awareness with every situation or challenge encountered.

Problem-Solving Skills: Every welding project presents unique challenges. A skilled welder can analyze the situation, identify potential problems, and implement effective solutions.

Communication Skills: Effective communication with clients, engineers, and other team members is crucial for ensuring that the welding project meets all requirements.

Adaptability: The ability to adapt to different work environments, materials, and welding techniques is essential in a dynamic field.

In conclusion, the history of welding is a testament to human ingenuity and the enduring pursuit of manipulating metals to build and create. From the mystical practices of alchemy to the sophisticated techniques of modern welding, the journey has been one of continuous learning and innovation. When seeking welding services, prioritizing professionals with the right certifications, experience, and a commitment to quality, safety, and communication is paramount to ensuring the successful execution of any project. The modern metal artist, as we aptly describes them, plays a critical role in constructing the world around us, carrying on a tradition that spans millennia.